Innovations in Resilient flooring products has went through different milestones over the past. From the most conventional resilient homogeneous flooring to luxury vinyl tiles and many other type of resilient flooring products. With increasing movement to phase out application of Polyvinyl chloride in building materials, the next generation resilient flooring products are associated with application of different natural materials as well as PVC alternative polymers.

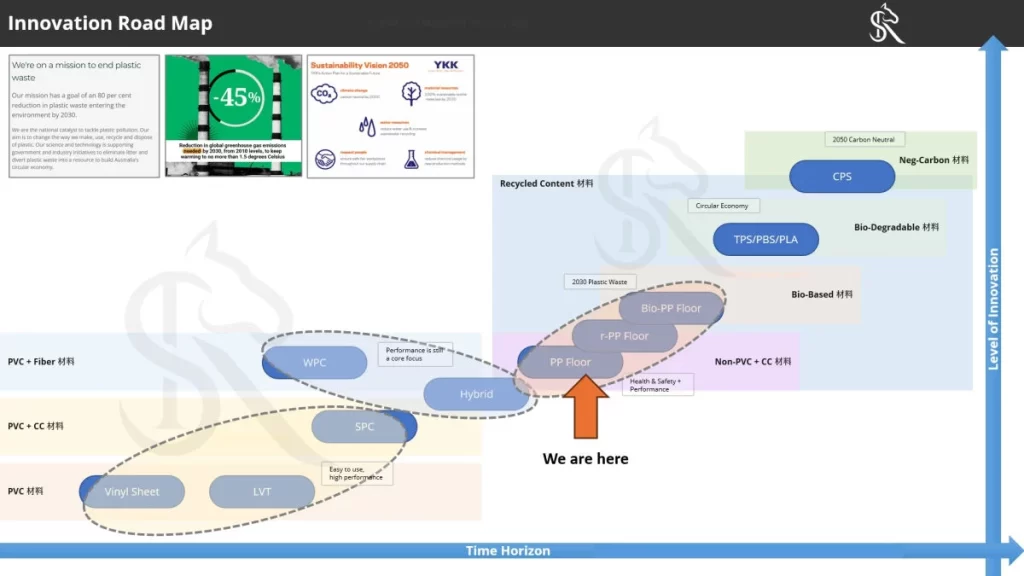

Innovation Roadmap for Resilient Flooring Compositions

The development for next generation LVP flooring products are associated with using Non-PVC compositions such as Polypropylene plastic or Polyethylene Terephthalate plastic. Both type of plastic are common plastics that are used in everyday consumable products, and therefore holds prominent outlook to replace PVC polymers.

The innovation roadmap above shows how conventional PVC composition has lead the development of vinyl sheet flooring to LVT flooring, SPC flooring and even hybrid flooring. The past product improvements has focus on easy to use features as well as improving product quality and performances.

As the new product development in resilient flooring begin to shift towards improving health and safety as well as environmental sustainability, new compositions are needed to effectively improve its environmentability and health safety performance. With consideration for circular economy in floorings, increasing recycled material content is the key for eco-flooring product.

What features are associated with Sustainability Flooring Products?

- Natural Materials

- Renewable Materials

- True Recyclability

- Made from Recycled Materials

- Biodegradable

- Low Carbon Footprint or Negative Carbon Footprint

Natural Materials in Flooring

Less plastic is a global trend that is associated with plutions we face from over productions from petrochemical products. While not all plastics are considered harmful, the generic perception on plastics still lead to plastic free flooring developments. Flooring made from natural materials are considered less toxic and even environmental friendly.

Note: Some wood species takes decades of time to grow, so not all natural material floorings fall under the definition as being sustainable. This is where the concept of renewable comes in.

Renewable Materials in Flooring

The concept for renewable means the material can be regrown with acceptable period of time. Therefore when it comes to renewable resources, the sustainability is associated with efficient the material can grow back and used. Common renewable materials in flooring currently include cork, bamboo, and Linoleum. Biobase polymers such as PLA is also considered renewable but consideration for food supply crisis as it is made from corn crops.

True Recyclability in Flooring

The recycling concept is generally about polymer based floorings. While flooring brands might claim that their polymer based flooring is 100% recyclable, which in theory all polymers can be recycled, in practice it is not. In fact, polymers such as PVC needs to go through a chemical recycling process which further increase chemical pollutions and increasing carbon footprint. Polymers such as Polypropylene (PP) and Polyethylene Terephthalate (PET) can be recycled mechanically so its recyclability value is higher.

Note: with natural materials, some flooring brands offer takeback scheme with refurbish treatments to allow a Second-Life for its flooring products. Good job for brands such as Lico, Gerflor, Coretec.

Flooring Made of Recycled Materials

Increasing recycle contents in flooring composition is now actively implemented by brands such as Shaw, Mohawk, Gerflor, Tarkett, Ceramin and many more. Recycled materials from either plastics and natural wood fibers are common but each with different challenges. Unilin for example has launched the project to recycle HDF materials since 2021, and in 2024 has established its pilot plant in France to recycle all its laminate flooring products.

However, even with advanced recycling technology from Unilin, the current limitation still exist in effectively selecting the right quality of laminate to recycle. This is due to the fact that different manufacturers use different grade of HDF, even the toxic ones, and so with Unilin’s pilot recycling plant, they only work with Unilin’s own product to ensure recycled material consistency in quality.

Biodegradable Materials in Flooring

Flooring made from natural fibers are naturally biodegradable as they are biobased. With plastic based flooring, this can be a significant challenge for the flooring industry. While there are polymers such as PLA, PBS, PBAT, however these type of plastics are very limited with production scale and material costs are significantly higer compare to the likes of PVC, PP, PET plastics.

Further concern with biodegradable plastics are its required conditions to effectively biodegrade. Unfortunately biodegradable plastics does no biodegrade unless its in a industrial compost setting, which rarely happens in a natural environment.

Low Carbon / Negative Carbon Materials in Flooring

The concrete industry is more advanced in terms of drying to reduce carbon emission from its manufacturing and product life time. Many technology companies in Europe has already launched addtive products that hekp to reduce carbon emission from concretes.

For resilient flooring industry, there is currently not as much progress in terms of developing material solutions that reduce carbon emission. However, here at at Hengdi we believe this is an approach which later innovations in resilient flooring products would advance to.