Discovering the Ideal Specification for Vinyl Flooring Import Solutions

In the ever-evolving products for interior design and home improvements, understanding the specification design in the flooring products are essential to support consumers to select the ideal specification for vinyl flooring product collections. As resilient vinyl flooring is a versatile and cost-effective option, the product has gained strong popularity among homeowners and professionals alike. However, to make better informed choices, flooring business must delve into the various specifications that define these different flooring products.

This article will explore vital aspects of vinyl flooring and help you navigate the vast array of options available today, ensuring you select flooring solutions that best meet your needs.

Why product specifications are important for Vinyl Flooring Businesses?

When it comes to vinyl flooring choices, product specifications play a crucial role in determining the quality, durability, and suitability of the flooring for different rennovation projects. Understanding these specifications can significantly impact consumer satisfaction and product life time.

Therefore, the importance of product specifications cannot be overstated. They encompass various elements such as material composition, thickness, wear layers, and installation methods. Each of these components contributes to how well the flooring performs under the conditions they are set in. For example, if the flooring are installed in a high-traffic area, vinyl flooring with a thicker wear layer will be necessary to withstand longer daily wear and tear effectively.

Moreover, specifications also align with local market preference. As consumer preferences can vary significantly across demographics, geographic locations and professionals. When targeting specific markets, floor businesses should ensure that their product specifications meet the customers’ required specifications. A thorough understanding of ideal specifications can lead to tailored offerings that appeal directly to consumer needs, leading to enhanced sales and brand loyalty.

In addition to customer satisfaction, adhering to industry standards in product specifications helps flooring businesses and flooring brands to avoid potential legal issues arising from inferior flooring products. By ensuring that their resilient flooring products meet the industry required standards, flooring companies are more protected from possible liabilities. Building trust between flooring manufacturers will also allow flooring businesses to build more secure international supply chain for their products.

Understanding Product Needs

One key factor in determining the appropriate product specifications for vinyl flooring is understanding the product needs. It is apparent that different type of consumers will have different preference in vinyl flooring specifications. For example when it comes to rental property renovations, entry price point dry back LVT are more popular. And when it comes to residential DIY projects, rigid core SPC with click n lock system will be more popular.

Quality Over Quantity

When creating resilient vinyl flooring product collections, it’s not just about offering numerous options; it’s about providing high-quality choices. Brands must curate their vinyl flooring collections to highlight superior specifications, such as robust wear layers and dimensional stability.

While entry-level LVT products may attract price sensitive buyers, premium specifications can captivate higher end customers that are willing to invest in high quality and performance. It’s essential for floor companies to strike a balance between affordability and quality, catering to diverse market segments while maintaining a reputation for excellence.

Ongoing Communication with Customers

Finally, maintaining open communication with customers about product specifications is critical. This involves updating them on innovations in latest vinyl flooring technology and materials, which can significantly enhance performance and durability. These unique advantages and value proposition can reinforce brand value and encouraging customer loyalty.

Type of Vinyl Floorings by Installation Methods

Understanding the different types of vinyl flooring installations is essential when considering product specifications for different type of projects. Not only does each installation method impact the practicality of the business, but it also influences the overall cost of ownership for consumers.

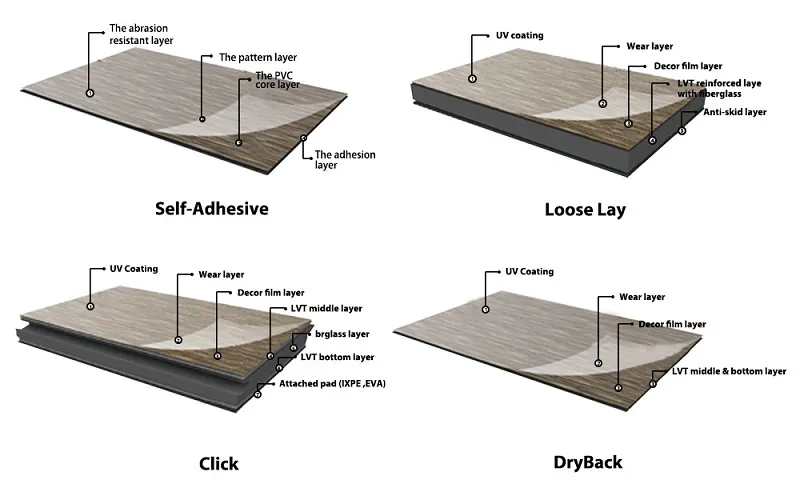

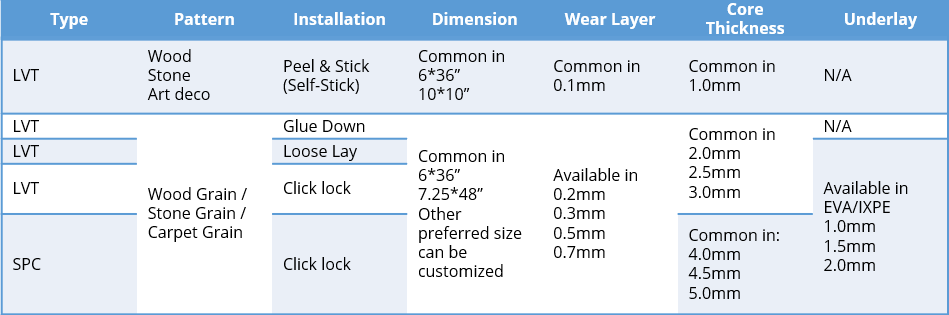

Vinyl flooring tiles typically falls into four main categories based on their installation methods: Peel & Stick, Glue Down, Loose Lay, and Click & Lock (Interlocking). Each of these methods offers unique benefits and challenges that can affect consumer preferences and market viability.

As we delve deeper into each type, it’s crucial to consider factors such as ease of installation, thickness, and durability. This knowledge enables customers to make informed decisions, ensuring they choose an option that meets their specific needs.

Peel & Stick (Self-Stick) Installation

Peel & Stick vinyl flooring is renowned for its user-friendly installation process. Designed specifically for DIY enthusiasts, this method allows homeowners to quickly transform their flooring space without the need for professional assistance. The adhesive backing permits straightforward application, just simply peel off the protective layer and stick it onto a clean surface on the floor.

While vinyl flooring thickness generally remains low in Peel & Stick applications, commonly between 0.8mm to 1.2mm thickness, it does not compromise its popularity. In fact, many consumer find it more convenient as it is more easily to be cut into any required shapes even with a curve. This offers temporary and quick-fix solution for consumers. However, it’s essential to note that the thinner design poses several challenges, making it less ideal for long-term interior use.

A common concern among users is the tendency for these tiles to experience contraction, expansion, and curling over time. While a quick fix for aesthetic improvements, Peel & Stick options often require periodic replacements, which overtime can become burdensome for homeowners seeking lasting solutions.

SPEC Design in Peel & Stick

The design specifications of Peel & Stick vinyl flooring typically feature a semi-rigid structure. The thin wear layer may limit its durability but allows for easy cutting and shaping when adapting to unconventional layouts. When installed around fixtures such as toilets or corners, this versatility becomes particularly advantageous.

Moreover, the appeal of Peel & Stick vinyl flooring largely lies in its affordability, making it a popular choice among budget-conscious consumers. However, businesses should remain transparent about the limitations of this option. Encouraging customers to consider their long-term needs will foster trust and lead to more viable recommendations.

Glue Down Installation

Glue Down vinyl flooring requires an adhesive application for the installation, which may deter some DIYers. However, it boasts several advantages, particularly in terms of stability and long-term performance. With a thickness ranging from 1.0mm to 3.0mm, glue down options are generally more robust than their Peel & Stick counterparts.

This method offers better dimensional stability due to the added layer of fiberglass often incorporated into the design. While it requires additional time for proper installation, the end result is often worth the effort. Consumers seeking durable flooring solutions for high-traffic areas will likely find Glue Down options appealing, as they can withstand significant wear and tear over time.

Nevertheless, the process of removing glue down flooring can be challenging. Homeowners must prepare the subfloor adequately before installation, which adds another layer of complexity. Companies should emphasize the pros and cons of this method when promoting their products, helping customers make educated decisions that suit their lifestyles.

SPEC Design in Glue Down

The specification design for Glue Down vinyl flooring includes semi-rigid luxury vinyl tiles (LVT) with a focus on enhancing stability and longevity. The thickness variation allows for adaptability across various environments, from residential settings to commercial establishments.

Brands that prioritize sustainability may incorporate eco-friendly adhesives in their glue down options. This consideration aligns with growing consumer awareness of environmental impacts, further elevating market appeal. Businesses should not shy away from promoting the ecological benefits of their floorings, as this could strengthen their brand image and attract environmentally conscious customers.

Overall, Glue Down vinyl flooring appeals to those prioritizing durability and stability, while manufacturers can leverage this knowledge to create targeted marketing messages that resonate with potential buyers.

Loose Lay Installation

Loose Lay vinyl flooring is distinguished by its absence of adhesives, allowing for effortless installation and removal. This feature makes it particularly attractive to renters or those seeking temporary flooring solutions. The thickness of Loose Lay options typically ranges from 3.0mm to 7.0mm, offering enhanced stability compared to Peel & Stick alternatives.

Although the lack of glue simplifies installation, it raises concerns regarding water leakage. Consumers should be made aware of potential risks associated with inadequate seams, which can lead to water infiltration and damage over time. Understanding these nuances is crucial for guiding customers toward the best choice for their specific environments.

SPEC Design in Loose Lay

Loose Lay vinyl flooring comes in various formats, including both semi-rigid LVT tiles and rigid-core SPC planks. The inclusion of an underlayment may further improve stability, particularly for SPC products. This added cushioning enhances comfort and minimizes noise transmission, making Loose Lay options particularly suitable for multi-story buildings or spaces where sound control is essential.

The flexibility offered by Loose Lay vinyl flooring is another significant advantage. Homeowners can easily replace or reposition individual tiles without disrupting the entire layout. For those who enjoy experimenting with interior design, this feature allows for creativity without commitment.

While the ability to remove and reuse Loose Lay vinyl flooring is undeniably appealing, it’s important to inform customers about optimal care practices. Proper maintenance will prolong the lifespan of the flooring and keep it looking fresh and vibrant for years to come.

Click & Lock (Interlocking) Installation

Click & Lock installation, often regarded as an upgrade to Loose Lay options, provides an innovative solution for ease of use. Featuring interlocking systems along the edges, these vinyl planks offer a secure and stable fit, reducing water penetration between joints and enhancing overall performance.

The thickness of Click & Lock vinyl flooring typically ranges from 4.0mm to 9.0mm, contributing to its robust structure. With improved waterproof capabilities, these products cater to consumers seeking stylish yet functional flooring solutions for kitchens, bathrooms, or other moisture-prone areas.

SPEC Design in Click & Lock

The specification design of Click & Lock vinyl flooring emphasizes ease of installation and superior resilience. With Uniclic technology facilitating seamless connections between planks, homeowners can complete installations in record time. This efficient approach appeals to busy consumers who might otherwise hesitate to engage in time-consuming renovation projects.

Furthermore, the click-and-lock mechanism minimizes the risk of movement once the floor is laid, ensuring long-term stability. Manufacturers can capitalize on this strength by emphasizing the ease of use in their marketing materials. Additionally, educating customers on proper installation techniques can further enhance satisfaction and minimize potential complaints related to misalignment or instability.

Common Specification in Different Type of Vinyl Floorings

As the vinyl flooring market continues to grow, it’s crucial for manufacturers to establish a clear understanding of common specifications. These specifications for vinyl flooring provide insight into product versatility, performance, and overall marketability.

Across various types of vinyl flooring, certain specifications consistently emerge as critical selling points. From thickness to wear layer quality, these elements dictate the suitability and attractiveness of individual products.

Wear Layer Thickness

Wear layer thickness serves as a primary indicator of durability in vinyl flooring. Generally measured in mils, this protective layer shields the core material from scratches, stains, and daily wear. Thicker wear layers are often preferred in high-traffic areas, as they resist damage and extend the lifespan of the flooring.

Consumers should be well informed about the differences between various wear layer thicknesses. An informed customer is more likely to appreciate the value of investing in higher-quality products, leading to greater satisfaction and long-term loyalty.

Core Material Composition

The core material used in vinyl flooring plays a significant role in stability and performance. Traditional vinyl often features a flexible core, while newer options include rigid-core variations made from stone polymer composite (SPC). Rigid cores provide additional support and structural integrity, making them ideal for uneven surfaces.

Brands that invest in high-performance core materials will likely differentiate themselves in a competitive marketplace. Promoting these advancements allows businesses to position themselves as leaders in innovation, attracting consumers seeking cutting-edge solutions.

Conclusion for Setting Ideal Specification for Vinyl Flooring Products

In conclusion, understanding the ideal specification for vinyl flooring is crucial for both consumers and flooring businesses alike. By delving into the intricacies of product specifications, individuals can make informed decisions that align with their needs and preferences. The exploration of different installation methods sheds light on the unique benefits and challenges each vinyl flooring type presents.

As the flooring industry continue to change, constant communication with customers, a keen awareness of market trends, and a commitment to quality will empower floor brands to thrive. Whether your business is considering entering the vinyl flooring market or expanding as a new product portfolio, staying attuned to specifications and product demand will undoubtedly yield success.