Polyvinyl chloride (PVC) has been widely applied into sectors such as building materials and synthetic flooring products. Due to its cost effective and versatile quality to create different type of resilient flooring products, it is the most commonly used composition across the resilient flooring industry. However, with increasing concerns over PVC composition, a call for PVC alternative materials are needed. As apart of the mega trend to phase PVC based flooring, polymers such as Polypropylene, PET, and PETG has merged as a alternative solution for the next generation resilient flooring products. Manufacturers across Asia, and China are working towards these alternative polymer solutions with their betting as the market has yet to decided which type of polymer composition will out perform. Here in this article, we will compare the natural properties of PP, PET, and PETG, and explain why we consider polypropylene is a superior alternative material for PVC.

Polypropylene, PET, and PETG Polymer Features

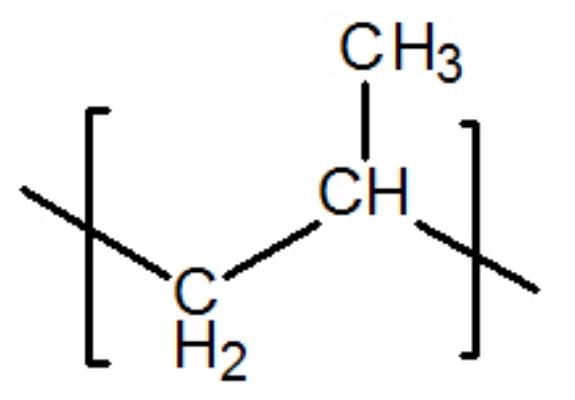

Advantages of Polypropylene (PP)

1. Excellent heat resistance to deform

Polypropylene polymer is a thermoplastic that can withstand high temperature conditions. While the glass transition temperature for polypropylene is only -10°C, being a crystalline plastic it has a heat distortion temperature at around 110°C. This means polypropylene products will have an improved dimensional stability as it is less likely to deform from temperature change.

2. Excellent resistance to bending fatigue

Polypropylene has excellent flexibility and can withstand repeated bending and deformation without breakage. An ideal property for both LVT and SPC flooring which meets the requirements for tenacity.

3. Chemical corrosion resistance

Polypropylene is a very stabilized polymer which makes it resistant to most chemical substances. Modified polypropylene composition will also carry this property to resist erosion from acids, alkalis, salts and other substances.

4. High Crystallinity

The high crystallinity property in polypropylene makes it ideal for manufacturing transparent wear layers for LVT and SPC floorings.

Disadvantages of Polypropylene

1. Susceptible to UV Ray

Polypropylene polymer is more susceptible and prone to degradation with UV ray exposure. Over extend period of UV ray exposure, Polypropylene can become more brittle.

2. Susceptible to Ink Adhesion Issue

Polypropylene being a non-polar plastic, has to be chemically treated to allow adhesion of ink onto the polypropylene substrate. It is currently an on going challenge as film manufacturer has to consistently work on the formulation of polypropylene water solutions to enhance the printing performance onto the polypropylene print films.

Advantages of Polyethylene Terephthalate (PET)

1. Excellent Transparency

Polyethylene Terephthalate PET polymer has excellent transparency.

2. Excellent Mechanical Properties

PET composition has mechanical properties that make it suitable for making semi-rigid LVT and rigid core SPC flooring. The rigidity and tenacity allows it to form planks and sheets.

3. Wide range Source of Recycled PET

As one of the highest used polymer for single use drinking bottles, there are no better source of recycled PET materials on the market. PET based LVT and SPC has an advantage with increasing recycled contents in its material composition.

Disadvantages of Polyethylene Terephthalate (PET)

1. Susceptible to Yellowing

PET polymer is prone to yellowing as it is easily oxidized during its long life span.

2. Susceptible to Higher Temperature and Deform

PET has a heat distortion temperature range between 60°C and 80°C. This means PET based vinyl flooring will more likely to have dimensional stability issue from expansion and contraction when dealing with temperature change. Imported PET LVT and SPC will also have similar problem as container of goods are shipped across the ocean where day and night temperatures fluctuate more significantly.

3. Low scratch resistance

PET surface does not have sufficient hardness to withstand scratches and wears.

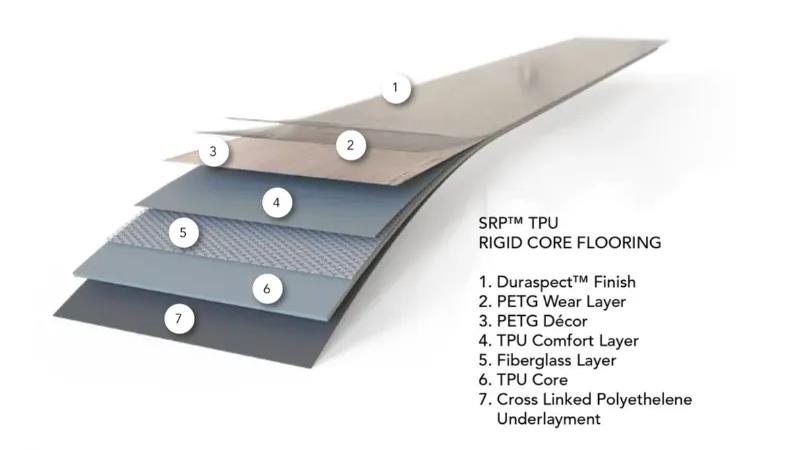

Advantages of Polyethylene Terephthalate Glycol (PETG)

1. Excellent Processing Performance

PETG is more easily processed to molding. This means planks and sheets of PETG can be extruded with higher efficiency.

2. Greater Recyclability in PETG

PETG polymers are generally recyclable.

3. Excellent Transparency

PETG transmittance can reach up to 90%, therefore can create wear layers with improved transparancy.

4. Excellent 3D printing performance

Out of the three type of polymers mentioned in this article, PETG flooring has the best 3D printing quality and performance. The substrate of PETG can easily adhere with ink.

Disadvantages of Polyethylene Terephthalate Glycol PETG

1. Higher Cost

PETG has a higher raw material costs compare to PET and PP polymers. This put PETG flooring at a comparative disadvantage over price.

2. Low Heat Distortion Temperatures

PETG has a relatively poor heat resistance compare to PP and PET compositions. With distinctive lower heat distortion temperatures, PETG LVT and PETG SPC are more susceptible to dimensional change and deformation.

Comparison Chart for PP, PET, and PETG Polymers

| PP | PET | PETG | |

|---|---|---|---|

| Heat Distortion Temperatures | 90-100°C | 70-80°C | 65-75°C |

| UV Resistance | Moderate | High | Moderate |

| Chemical Resistance | Excellent | Good | Moderate |

| Impact Resistance | High | Moderate | High |

| Flexibility | Less flexible | Less flexible | More flexible |

| Transparency | Less transparent | Less transparent | More transparent |

| Recycling | Not entirely recyclable | Generally recyclable | Generally recyclable |

| Ease of Processing | Easier to mold | Requires pre-drying for molding | Easier to mold |

| 3D Printing Performance | Moderate, can be brittle and prone to warping | Moderate, can be brittle | Excellent, strong and flexible |

Why Hengdi consider Polypropylene Luxury Vinyl Flooring will be the next generation resilient flooring?

When it comes to mechanical performances, there is no doubt that polypropylene based LVT and SPC will out perform the quality of PET-based resilient flooring or PETG-based resilient flooring. The distinctive advantages in PP composition compare to PET and PETG composition lays in its impact resistance, chemical resistance, and cost effectiveness features.

Engineering Modified PP Polymer for Resilient Flooring Manufacturing

With increasing demand for PVC-Free resilient flooring products, polypropylene (PP) composition comes in play as one of the most prominent LVT and SPC flooring product. Some of the inferior properties, when compare with PVC, such as fire retardant performance and adhesive issue, can be improved through composition modification.

Hengdi as a Polypropylene LVT / SPC Manufacturer in China

Working with leading resilient flooring R&D company, Hengdi floor has proudly launched our in-house manufactured Polypropylene flooring products. Our in-house PP-LVT and PP-SPC are processed from raw materials to the assembly of different layers in resilient flooring together.

Talk to us to learn how Hengdi can support your flooring business with propylene resilient flooring collections.